-

Product

-

-

-

-

-

Language

Product Video

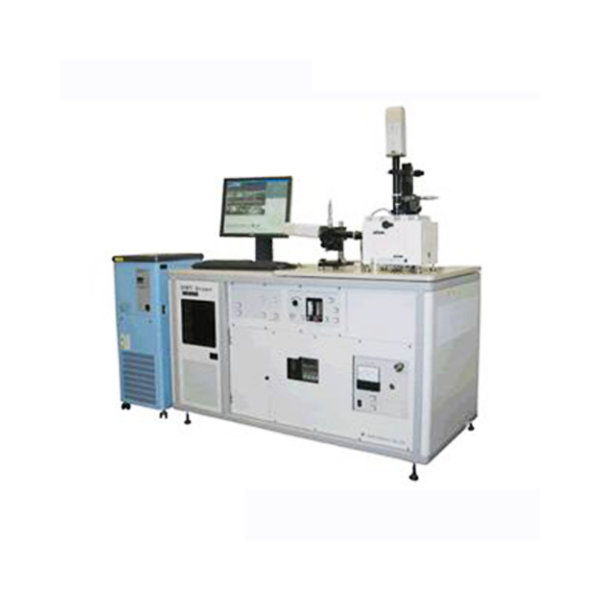

Product Overview

Product Features

· Observable sample size is 50×50mm, and large components can also be observed.

· Maximum heating temperature can reach 800°C.

· Uses near-infrared halogen heating element; the top and sides of the sample are heated by radiation, and the bottom of the sample is heated by stage heat conduction, enabling uniform all-around heating of the sample.

· Maximum heating rate is 250°C/min (approximately 4.2°C/sec). The temperature curve can be set in units of 1°C and 1 second, with up to 127 stages adjustable.

· Top and side observations can be performed simultaneously, preventing missed views and ensuring high observation accuracy; the inclined observation angle can be adjusted from 0 to 15 degrees relative to horizontal. Continuous observation of BGA and CSP during melting and solidification processes is possible. Additionally, deformation of printed circuit boards during heating and cooling can be observed. With a resolution of 10μm, the size of solder paste powder particles can be observed.

· Magnification on a 17-inch monitor ranges from 8 to 260 times, allowing optimal magnification for samples from 0603-sized chip components to BGA packages. Custom products capable of 520 times magnification on a 17-inch monitor are available upon special request.

· Uses gas flow replacement tools to circulate gas inside the heated chamber, removing smoke generated by the sample and gaseous organic substances from the heating chamber. This prevents image quality degradation caused by smoke and gaseous organics, ensuring stable high-quality images.

· Images displayed on the monitor and recorded on the hard disk can include annotations such as ① temperature inside the heating chamber, ② elapsed time since heating started, ③ test length records or reference scales, and ④ sample characteristics and sample numbers, which can be easily inserted.

· Based on this information, the real-time state of the sample can be observed on the image during temperature changes.

· Animated image data is digitized and stored on the hard disk in MPEG-2 encoded format to prevent image quality degradation.

· Animated image recording uses HD (hard disk) to record top and inclined observation images. Each observation surface uses a 140GB hard disk, totaling two disks, with approximately 40 hours of recording time each.

· Nitrogen gas is circulated inside the heating chamber to replace air, creating a nitrogen environment. By using a flow replacement nitrogen environment combined with an oxygen concentration meter and gas flow replacement tool, the oxygen concentration inside the heating chamber can be controlled to a desired value, even during heating.

· Heating can be performed in a vacuum environment at a level of 13 Pa.

· Solder reflow temperature curve of 3 to 4 minutes, with 5 to 6 samples tested per hour (including heating chamber cooling time).

Daily maintenance:

Using the included dedicated joystick, daily maintenance of the observation window can be completed within 30 seconds; the difficulty level of this maintenance is comparable to inserting a sample into the main unit, reducing the engineer's workload. Additionally, cleaning inside the heating chamber does not require other joysticks and can be completed in 3 to 5 minutes. Major disassembly of the heating chamber is basically unnecessary.

Operating environment requirements:

This device requires commercial power supply and cooling water; power input requirement is AC 100V.

Product Specifications

Product Advantages

Application Areas

Most suitable for the evaluation and analysis of glass paste, silver, and copper-tin paste.

Recommended Products

FAQ

Online Message

If you are interested in our products, please leave your email to get a free quotation, thank you!

OUTLETS

Service Outlets

Shanghai-Head Office

Shanghai Hapoin Enterprise Development Co., Ltd.

Address: Building 6, Southern Metropolis Garden, No. 1165, Jindu Road, Minhang District, Shanghai

Telephone:+86 150 2686 5822

Email:info@hapoin.com

Shenzhen Branch

Shenzhen Hapoin Ruihe Technology Development Co., Ltd.

Address: Room 302, 3rd Floor, Building B, Kaicheng High-tech Park, Dalang Street, Longhua District, Shenzhen

Telephone:+86 0755 2223 2285

Email:sales@hapoin.com

Hong Kong Branch

HAPOIN ENTERPISE LIMITED

Address: Unit 917A, 9/F., Tower A, New Mandarin Plaza, No. 14 Science Museum Road

Telephone:+00852 61187991

Email:sales@hapoin.com

Vietnam Branch

HAPOIN VIETNAM

Address: 6th Floor, CTM Office Building, No. 139, Zhipiao Road, Zhipiao District, Hanoi, Vietnam

Telephone:+84 398 848 969

Email:sales@hapoin.com

Japan Branch

HAPOIN CO., LTD.

Address: 6th Floor, 2-3-8 Iwamotocho, Chiyoda-ku, Tokyo

Telephone:+81 070 9356 1267

Email:sales@hapoin.com

Kunshan Office

Kunshan Office

Address: 10th Floor, Building B, Modern Plaza, No. 8, Weiye Road, Yushan Town, Kunshan City

Telephone:+86 150 2686 5822

Email:sales@hapoin.com

Taipei Branch

Uniwin Chemical Co.,LTD.

Address: No. 14, Alley 3, Lane 250, Section 2, Huanhe South Road, Taipei 10853

Telephone:+886 02 2336 2202

Email:sales@hapoin.com

Beijing Office

Beijing Office

Address: Room 306, Building 4, Zhongtou Oriental, West Zhihe North, Chaoyang District, Beijing

Telephone:+86 150 2686 5822

Email:sales@hapoin.com

Contact Number

Headquarter Address

6, South Metropolis Garden, No. 1165, Jindu Road, Minhang District, Shanghai

Follow the official account

Follow the video account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.