-

Product

-

-

-

-

-

Language

BGA Rework Station

DIC

RD-500V/RD-500SV

Product Video

Product Overview

Introduction to DIC RD-500V/RD-500SV BGA Rework Station:

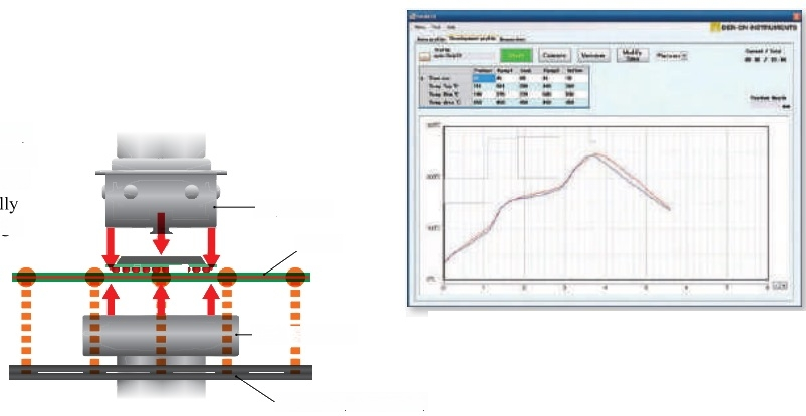

Soldering of micro components is a difficult task that only specific operators can perform. Especially for 0402 (01005), which often involves substrates with high packaging density, heat impact on adjacent components can cause secondary defects. This machine changes the way hot air is conducted through the accessory top, directly contacting the component to be reworked, enabling the most effective rework of the target component without melting the solder of surrounding adjacent components.

|  |  |  |  |

Product Features

Features of DIC RD-500V/RD-500SV BGA Rework Station:

High-definition tomographic camera with clear images:

Using a high-definition tomographic camera with a 120x zoom distance lens, the alignment of molds and parts or very small components can be clearly confirmed with corresponding spare parts. Precise temperature control.

By sampling data at 10 times the interval of previous models, it achieves superior reproducibility and high-precision temperature control.

Precise temperature control:

By sampling data at 10 times the interval of previous models, it achieves superior reproducibility and high-precision temperature control.

Equipped with high-power, high-response heaters:

The top and bottom heaters are equipped with 1000W power, and the area heaters are equipped with six 600W rapid-response heaters (RD-500SV has four 500W heaters). High output and fast response speed allow immediate rise to the required temperature. Since the area heaters do not require standby preheating except during reflow heating, standby power consumption is greatly reduced.

Two types of pressure sensors:

During installation and removal, although the height values vary depending on the thickness of each part, the pressure sensor of this device can automatically determine the height and save the data. Two pressure modes can be selected depending on the situation.

Non-contact cleaning:

Using a soldering iron for substrate cleaning may damage the mold; especially delicate substrates require professional cleaning operators.

Automatic Z-axis control:

To accommodate slight differences in component nozzle height and control temperature changes, an inductive sensing method is used. The nozzle height is precisely controlled in 0.1mm increments. Values are set and automatically saved in the software.

Reducing temperature differences in the machine body:

Simple operation using the same settings across multiple devices.

Product Specifications

| Maximum Substrate Size | 500×700 mm (28”×20") | 400×420 mm (16"×17") |

| Component Size Range | 01005 (0402 mm) or larger | 01005 (0402 mm) or larger |

| Zone Heater | ±0.015 mm | ±0.015 mm |

| Power Supply | AC 200-240V 5.6kW | AC 200-240V 4.0kW |

| Top Heater | 1000 W | 1000 W |

| Bottom Heater | 1000 W | 1000W |

| Area Heater | 600 W × 6 IR 3600W | 500 W × 4 IR 2000W |

| Temperature Setting Range | 0 to 650℃ | 0 to 650℃ |

| Control | Windows10 | Windows10 |

| Display | LCD Monitor | LCD Monitor |

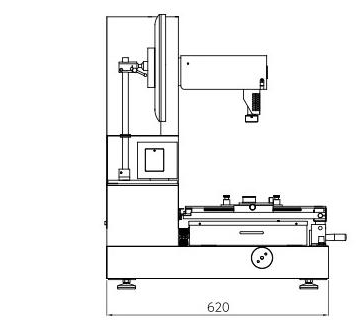

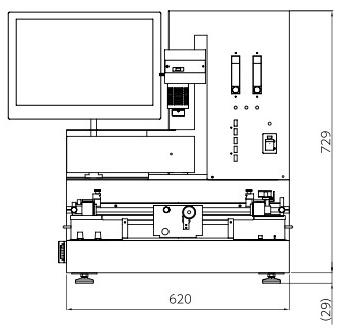

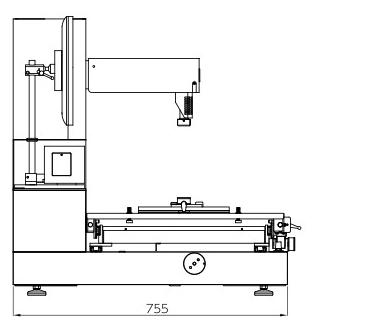

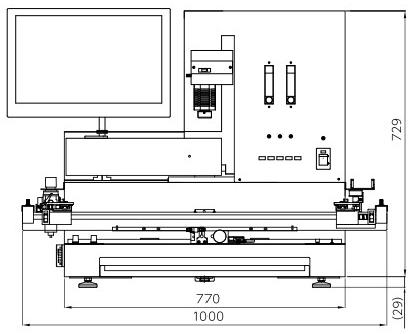

| External Dimensions (excluding protrusions) | 700W × 755D × 758H mm (27.55”W × 29.72"D × 29.84"H) | 620W × 620D × 758H mm (24.40"W × 24.40"D × 29.84"H) |

| Weight | 100 kg (220.46 lbs) | 70 kg (154.32 lbs) |

| Supply Air | 0.5 MPa 110 L/min (90 PSIG) | 0.5 MPa 110 L/min (90 PSIG) |

Product Advantages

|  |

Application Areas

Recommended Products

FAQ

Online Message

If you are interested in our products, please leave your email to get a free quotation, thank you!

OUTLETS

Service Outlets

Shanghai-Head Office

Shanghai Hapoin Enterprise Development Co., Ltd.

Address: Building 6, Southern Metropolis Garden, No. 1165, Jindu Road, Minhang District, Shanghai

Telephone:+86 150 2686 5822

Email:info@hapoin.com

Shenzhen Branch

Shenzhen Hapoin Ruihe Technology Development Co., Ltd.

Address: Room 302, 3rd Floor, Building B, Kaicheng High-tech Park, Dalang Street, Longhua District, Shenzhen

Telephone:+86 0755 2223 2285

Email:sales@hapoin.com

Hong Kong Branch

HAPOIN ENTERPISE LIMITED

Address: Unit 917A, 9/F., Tower A, New Mandarin Plaza, No. 14 Science Museum Road

Telephone:+00852 61187991

Email:sales@hapoin.com

Vietnam Branch

HAPOIN VIETNAM

Address: 6th Floor, CTM Office Building, No. 139, Zhipiao Road, Zhipiao District, Hanoi, Vietnam

Telephone:+84 398 848 969

Email:sales@hapoin.com

Japan Branch

HAPOIN CO., LTD.

Address: 6th Floor, 2-3-8 Iwamotocho, Chiyoda-ku, Tokyo

Telephone:+81 070 9356 1267

Email:sales@hapoin.com

Kunshan Office

Kunshan Office

Address: 10th Floor, Building B, Modern Plaza, No. 8, Weiye Road, Yushan Town, Kunshan City

Telephone:+86 150 2686 5822

Email:sales@hapoin.com

Taipei Branch

Uniwin Chemical Co.,LTD.

Address: No. 14, Alley 3, Lane 250, Section 2, Huanhe South Road, Taipei 10853

Telephone:+886 02 2336 2202

Email:sales@hapoin.com

Beijing Office

Beijing Office

Address: Room 306, Building 4, Zhongtou Oriental, West Zhihe North, Chaoyang District, Beijing

Telephone:+86 150 2686 5822

Email:sales@hapoin.com

Contact Number

Headquarter Address

6, South Metropolis Garden, No. 1165, Jindu Road, Minhang District, Shanghai

Follow the official account

Follow the video account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.